No products in the cart.

Return To ShopTop 5 Laser Level Questions FAQ

Laser Level Questions and FAQ

Over the years we have had literally thousands of laser level questions, so here are 5 of the most popular.

So here we go in no particular order, your laser level questions answered.

Can I buy a laser I can see outside?

Everyone would love to have a laser level where you can visibly see the laser at 50m or more in full sun. The quick answer is NO. Its just not possible due to the regulations on laser safety. The maximum allowed laser output in the construction industry is a class 3r (formally known as 3a) with <5mw output. Saying this the reality with this output is that you will not see a rotating beam more that a hand full of meters. A line laser maybe up to 10m if not too sunny and a dot laser maybe just about 20m depending on the surface its striking. A green dot maybe 40m see the redback D273G HERE

This is why laser level receivers were invented, in effect, to “see” the laser for you. A laser receiver with a rotating laser can work up to 300m diameter and with a quality pulsed line laser like the 1L360R, 2L360R and 3L360R up to 150m diameter. Dot lasers do not have receivers. So if you need to use a laser outside then ideally you need a laser which operates with a receiver.

If an auto levelling laser or dumpy level has a bubble vial, Do I need to get the bubble exactly in the center for maximum accuracy?

Some auto levelling lasers and all dumpy levels have a bulls eye bubble vial, why? These type of devices have a range that within they are able to auto level. For a laser level this can be between 3 to 10 degrees of the laser body of being out of level.

The older technology dumpy level this can be as little as 0.1 degree. To get the dumpy into self levelling range requires a bubble vial. With laser levels because this self levelling range is so much bigger a bubble vial is not essential. As you can visibly see a laser body that is outside this tolerance and simply adjust it to bring it into range. Also most laser levels have an audible or visual warning when its out of self levelling range so its pretty simple to fix up. What a bubble vial does do if fitted to a laser level like this, is to give you a better indication which way to adjust the body of the laser to bring it into self levelling range.

But, I haven’t answered the question yet! Does the bubble need to be set exactly in the center of bubble for maximum accuracy? The answer is NO. If the device is auto levelling and it is of good quality then as long as it is anywhere within range the accuracy will be exactly the same as setting the bubble in the center. For most devices this means if the bubble is mainly within the indicated circle.

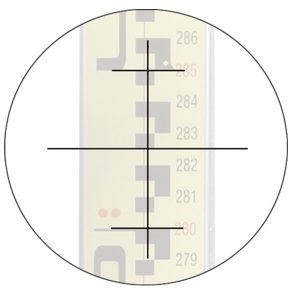

I can no longer see the cross hair lines on my dumpy level!

This used to be a very common question a decade or so ago when dumpy levels were sold far more that laser levels. But we do still get this question from time to time. This question normally crops up when the dumpy level has been borrowed or used by someone else. The cross hair needs to be focused in for each user depending on their eyesight. This adjustment is made by rotating the eyepiece that you look through. If the adjustment is taken to one extreme, then its possible for the cross hair lines to disappear all together for a particular user. By simply re-adjusting the eyepiece the lines will return into view.

How often do I need to get my laser calibrated?

Its a very simple question, with a not so simple answer. First of all a good quality laser or level that is treated well, not dropped or subjected to extensive vibrations, should not easily go out of calibration in the first place. So following this, you could say, a laser or level only needs calibration if it is out of calibration.

The best way of knowing if you laser is out of calibration is by self checking on a regular basis. Ideally before any major job. This is not necessarily a hard or time consuming thing to do. It can be as simple as levelling off a job and marking it out then moving the laser to the other side of the site and checking the levels you just made. Any inconsistency outside of operating tolerance should be easily spotted. A full guide to checking calibration can be found HERE. and a video below.

Some larger construction companies may have a policy of getting there equipment calibrated every 6 or 12 months. This is all well and good but do not assume because it was calibrated last week that its still good. Its always possible that the person to use it the day before dropped it and did not tell anyone. One last point just because someone else’s laser gives different levels to yours does not mean yours is to blame. The best way to self check calibration is by checking the laser against itself. See the video and link to guide linked above.

I’m using a laser level on site and I’m getting two or more level heights indicated on my receiver, Why?

Again a very common question. At the end of the day all a laser beam is, is light. Like all light it can be reflected by shinny surfaces like glass. A laser receiver cannot tell the difference between a laser directly from laser level or a reflected beam off a sheet of glass.

On a site with windows present its very possible for a laser to reflect off that glass. As the glass will almost certainly not be exactly vertical the laser beam will be deviated either higher or lower than its original path. In some circumstances the receiver will pick up both beams and so indicate two heights as being level.

This can be easily prevented by where you set up your laser on site. This is achieved by taking into account any shinny surfaces such as glass or metal structures. Set up so that the back of the receiver is facing the reflective surface. Then the receiver can no longer pick up any reflections off that surface. Note that machine receivers often have 360 degree coverage so this would not help. However, under most circumstances if a machine receiver is being used its unlikely close to a structure with glass.